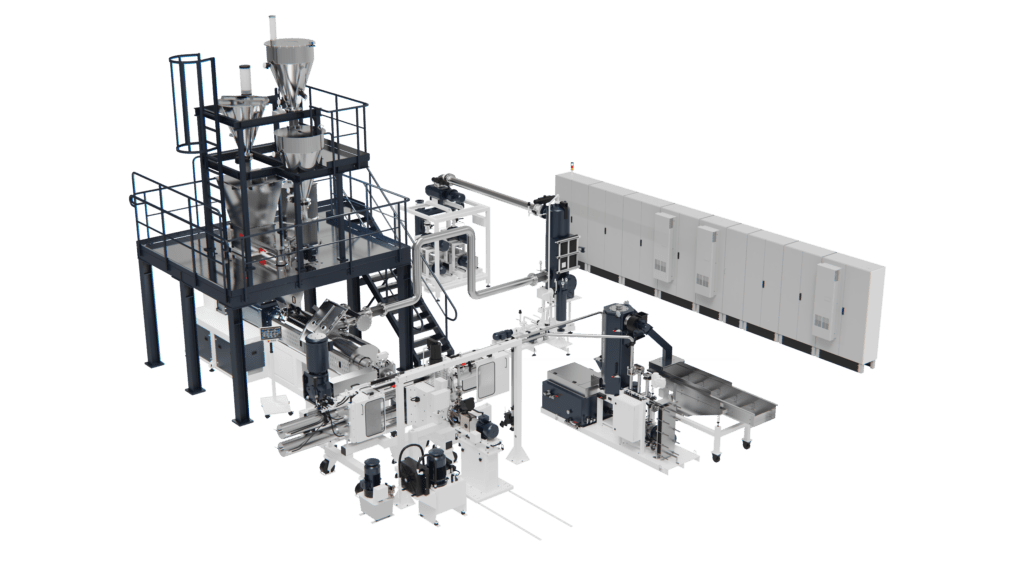

MAS extrusion lines are the ideal solution for processing PET, both in re-granulate and inline applications. All PET recycling and virgin material fractions such as bottle regrind, film regrind and pellets are processed together with additives in a single process. The patented conical design of the processing unit enables processing at low speeds and a high screw filling level over the shortest processing length at low melt temperatures.

Additionally, the concurrent twin-screw technology guarantees excellent homogenisation of fluctuating input material qualities as well as a large gas venting surface. This leads to outstanding intrinsic viscosity, color, and AA levels at very low energy consumption.

Depending on the application this can enable:

Secure your technological advantage in PET processing and contact the MAS experts!

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren