Conventional re-granulating systems with recycling extruder + melt filter + granulation are frequently limited in terms of potential output (kg/h) and quality of the produced granulate. MAS now offers an ideal solution: an upgrade extrusion line to operate existing recycling extruders, with decisively higher output levels at perfectly degassed granulate with better quality.

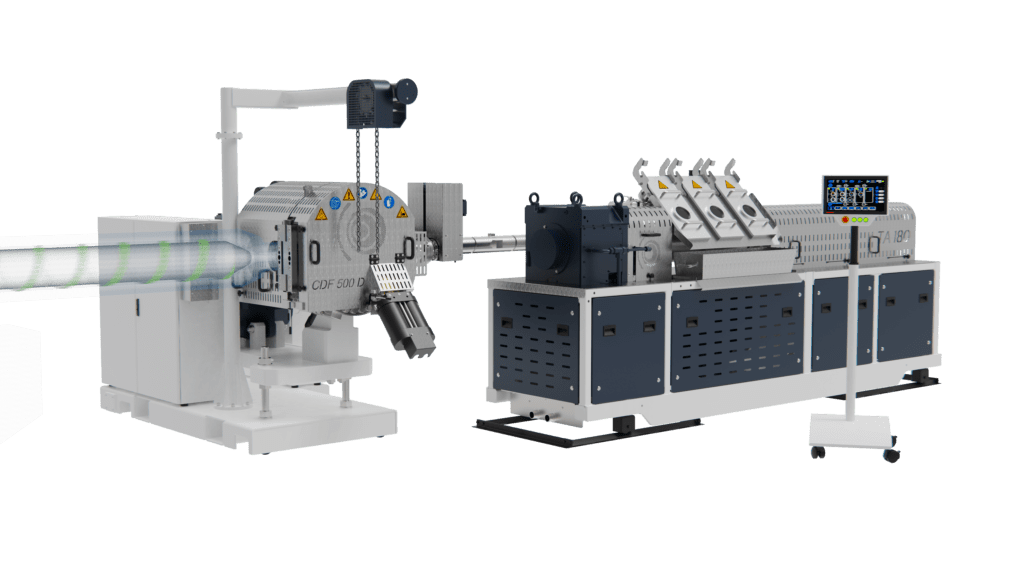

By exchanging the existing filter for the patented CDF melt filter type (continuous disc filter) - developed by MAS specifically for recycling applications - wooden parts, paper, non-melting plastics, rubber, and similar extraneous materials can be removed extremely efficiently and continually from the melt stream. Continual functionality eliminates the need to constantly and laboriously change the mesh screens, while also reducing personnel costs to a minimum.

Downstream of the CDF filter, a short single-screw extruder (standard length only approx. 13.5 L/D) equipped with a highly efficient, MAS-patented degassing zone, guarantees highest quality levels. The specifically developed degassing zone of the cascade is equipped with a melt distributor segment. Combined with optimally designed screw geometry, this generates a constantly revolving, maximum possible melt surface. Three generously dimensioned degassing domes with a vacuum pump calculated to the respective requirements ensure highly efficient degassing, even of difficult to process melts.

Greater performance, efficiency, and quality in the extrusion line thanks to MAS upgrades: Request an offer now!