EXTRUDER-HERSTELLER MAS

MAS ist Ihr innovativer Partner im Bereich

Kunststoff-Upcycling und Recycling

DOPPELSCHNECKEN-

TECHNOLOGIE

- Patentierte Verfahrenstechnologie

- Großes Einzugsvolumen

- Ausgezeichnete Homogenisierung

KOSTENOPTIMERTE

PROZESSE

- Höchste Energieeffizienz

- Nachhaltige Produktion

- Ausgezeichnete Homogenisierung

RECYCLING &

COMPOUNDING

- Maximale Flexibilität

- Maßgeschneiderte Produktion

- Compoundieren ohne Sidefeeder

WASCHEN OHNE

WASSER

- Effizientes Entfernen von Störstoffen

- Wasserfrei, nachhaltig, effizient

- Reinigung und Trocknung in einem Schritt

Innovation trifft Service

Mit unserem fundierten Know-how im Bereich des Kunststoff-Upcyclings und unserem Innovationsgeist entwickelt der Extruder-Hersteller MAS kundenorientierte, wirtschaftliche Lösungen. Die Perfektionierung der Technologie von Extruder-Maschinen und vielen weiteren hochwertigen Anlagen schafft neue Möglichkeiten, beste Resultate beim Recycling und Upcycling von Kunststofffraktionen aller Art zu erzielen.

Von der Anlagenplanung bis hin zur Wartung und Reparatur schaffen wir wegweisende, energieeffiziente und geprüfte Innovation für eine ressourcenschonende globale Zukunft.

Energie- und kostensparend

Höchstmögliche Qualität

Hohe Entwicklungstiefe

Innovative Lösungen

MAS — GLOBAL PLAYER

Mit Erfahrung und dem Wunsch nach positivem Wandel unterstützen wir weltweit Kunden und Spezialisten im Kunststoff-Recycling und ‑Upcycling. Mehr als 200 Kunststoff-Extruder mit Doppelschnecke sowie zahlreiche weitere MAS-Maschinen befinden sich aktuell im Einsatz, und es werden immer mehr. Unsere Vertriebspartner organisieren den umfassenden lokalen Service und Support.

Österreich

Schweiz

Frankreich

Benelux

Italien

Bulgarien

Großbritannien

Israel

Tschechien

Slowakei

Spanien

Portugal

Polen

Japan

Südkorea

Taiwan

China

USA

Mexico

Brasilien

Australien

Service & AftersaleS

Mit einem Team aus Experten bieten wir unseren Kunden eine Vielzahl an attraktiven Angeboten und Services, die weit über die Installation der Anlage hinausgehen. Maßgeschneiderte Betreuung, kurze Downtimes und laufende technische Weiterentwicklung sowie einfacher Komponententausch versprechen deutlichen Mehrwert für alle MAS-Kunden. Ihr Extruder-Hersteller sorgt stets für Innovation am neuesten Stand der Technik.

- Schulungen

- Maschinenoptimierung

- Serviceverträge

SERVICEHOTLINE

Mo-Fr:

Sa:

07:00 — 19:00 MEZ

08:00 — 15:00 MEZ

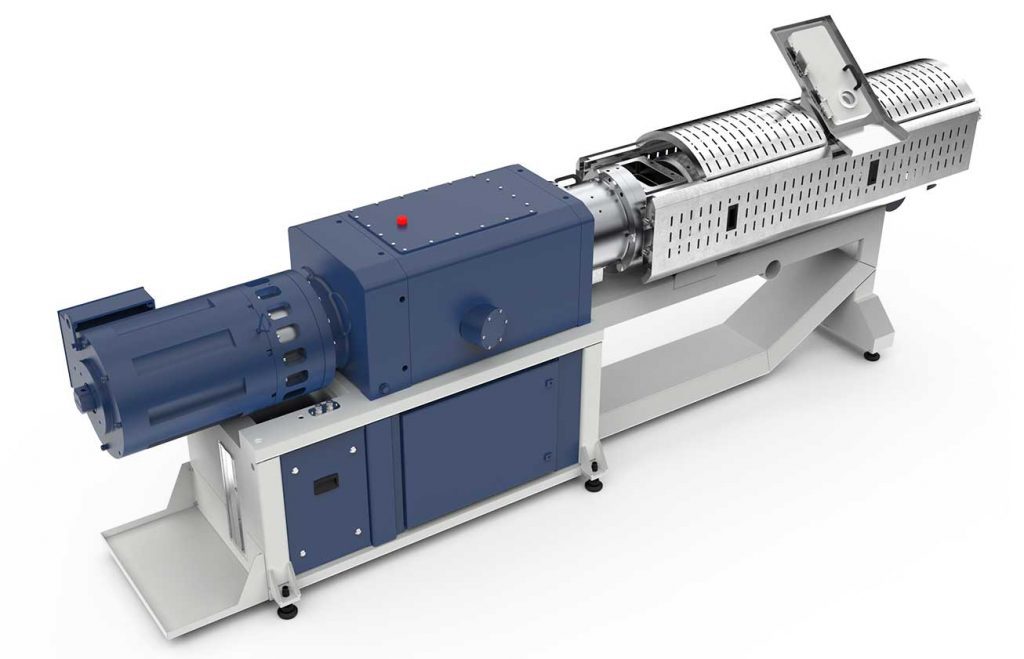

MAS-Doppelschneckentechnologie

Die volle Innovationskraft des Extruder-Herstellers MAS zeigt sich anhand des einzigartigen Doppelschneckenextruders. Dieser speziell für Recycling und Upcycling konzipierte Kunststoff-Extruder garantiert die schnelle und zugleich schonende Verarbeitung verschiedenster Plastikfraktionen, trennt ungewollte Zusatzstoffe und Einschlüsse vom Ausgangsmaterial und schafft besonders hochwertiges, reines Granulat. Entsprechend kann deutlich mehr vom Ausgangsmaterial verwertet und dem Recyclingkreislauf zugeführt werden.

- einfache Bedienung

- flexibel und anpassungsfähig

- schnelle und zugleich schonende Verarbeitung

- energiesparend und ressourcenschonend

- starke Entgasungs- und Reinigungsleistung

- wartungsarm

- platzsparend und nachrüstbar

- schneller und einfacher Kompinentenaustausch

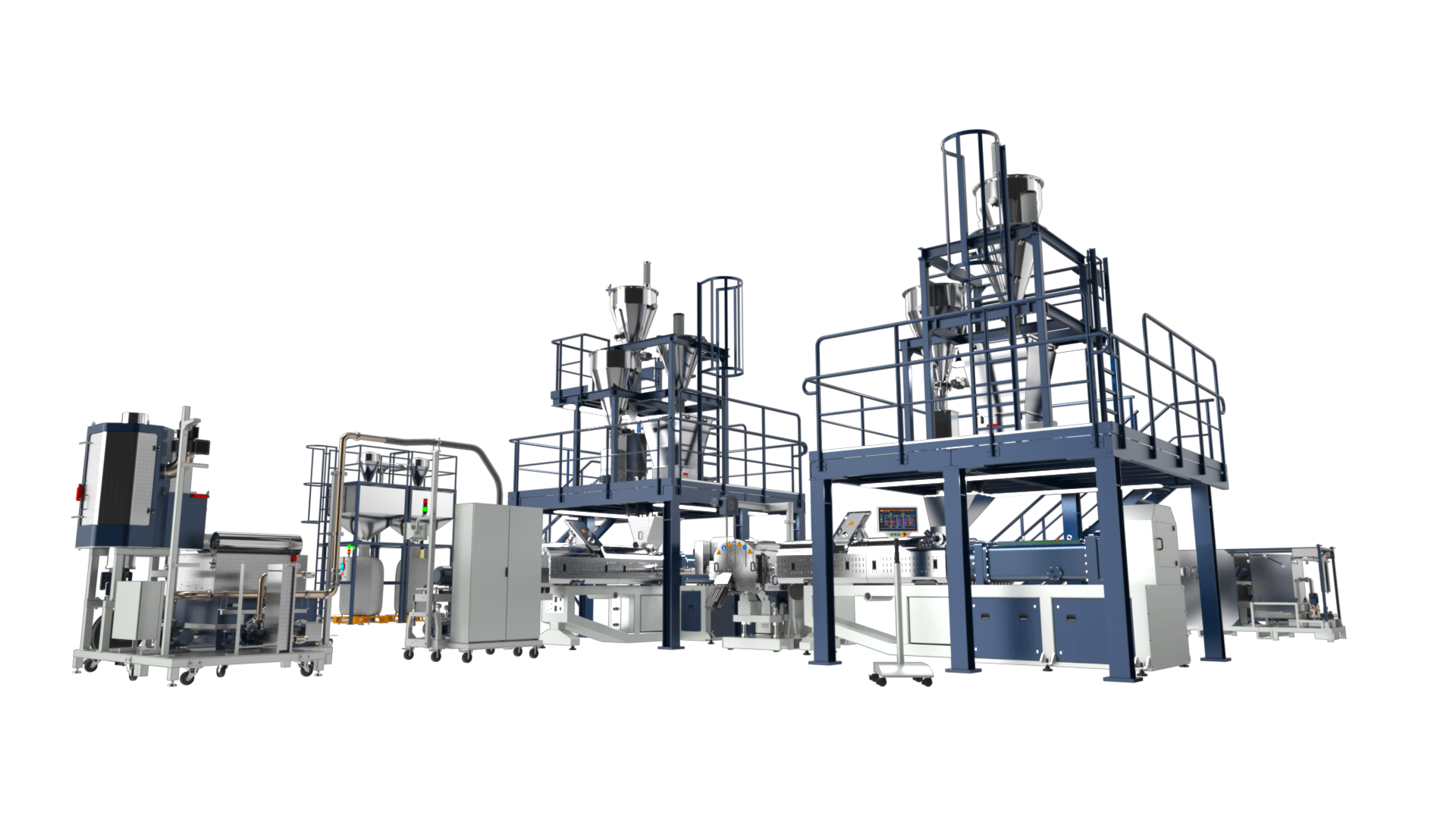

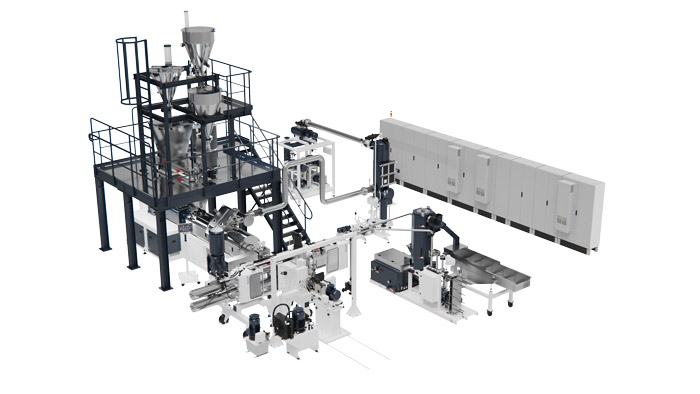

TWIN COMPOUND — INNOVATIV, EFFIZIENT Und FLEXIBEL

Das MAS-Twin-Compound-System bietet eine hervorragende Lösung für komplexe Compoundier-Aufgaben. Die zukunftsorientierte Technologie sorgt für die Optimierung Ihrer Prozesse und Steigerung Ihres Ertrags auf allen Ebenen.

Das Twin-Compound-Verfahren Ihres Extruder-Herstellers dient der Produktion von hochgefüllten Granulaten sowie Granulaten mit „dosierfähigen“ faser- oder pulverförmigen Zuschlagstoffen oder ähnlichen schwierig einzubringenden Additiven. Dabei agieren zwei MAS-Extruder in Serie mit einer bei Bedarf zwischengeschalteten Schmelzefiltration.

SIE FINDEN UNS AUF DIESEN MESSEN

Der Extruder-Hersteller MAS präsentiert sich auf ausgewählten Messen. Besuchen Sie uns und werden Sie Teil unseres MAS-Netzwerkes.

Nachhaltig, kosteneffizient, zukunftsorientiert.

Setzen Sie sich

mit uns in Verbindung

Sie möchten mehr über unsere Extruder‑, Upcycling- und Recycling-Lösungen erfahren? Sie suchen nach einer individuellen, maßgeschneiderten und zugleich innovativen Anlage, die Ihren Anforderungen entspricht? Unsere technischen Experten beraten Sie umfassend. Gerne nehmen wir Ihre Anfrage entgegen.

JOBS UND KARRIERE BEI MAS

Wir sind laufend auf der Suche nach neuen Mitarbeitern und freuen uns auf Ihre Initiativbewerbung!

Jetzt gleich auf unserer Karriereseite über aktuelle Jobs informieren!

SERVICEHOTLINE

Mo-Fr:

Sa:

07:00 — 19:00 MEZ

08:00 — 15:00 MEZ

ANLIEFERZEITEN

Mo-Do:

Fr:

08:00 — 15:30 MEZ

08:00 — 11:30 MEZ

WIR SIND FÜR SIE DA

Mo-Do:

Fr:

08:00 — 17:00 MEZ

08:00 — 12:00 MEZ

NEWSLETTERANMELDUNG

Exklusive News, Events und bahnbrechende Innovationen — Bleiben Sie mit unserem MAS Newsletter auf dem Laufenden!